Torrefaction of biomass for energy

Actions

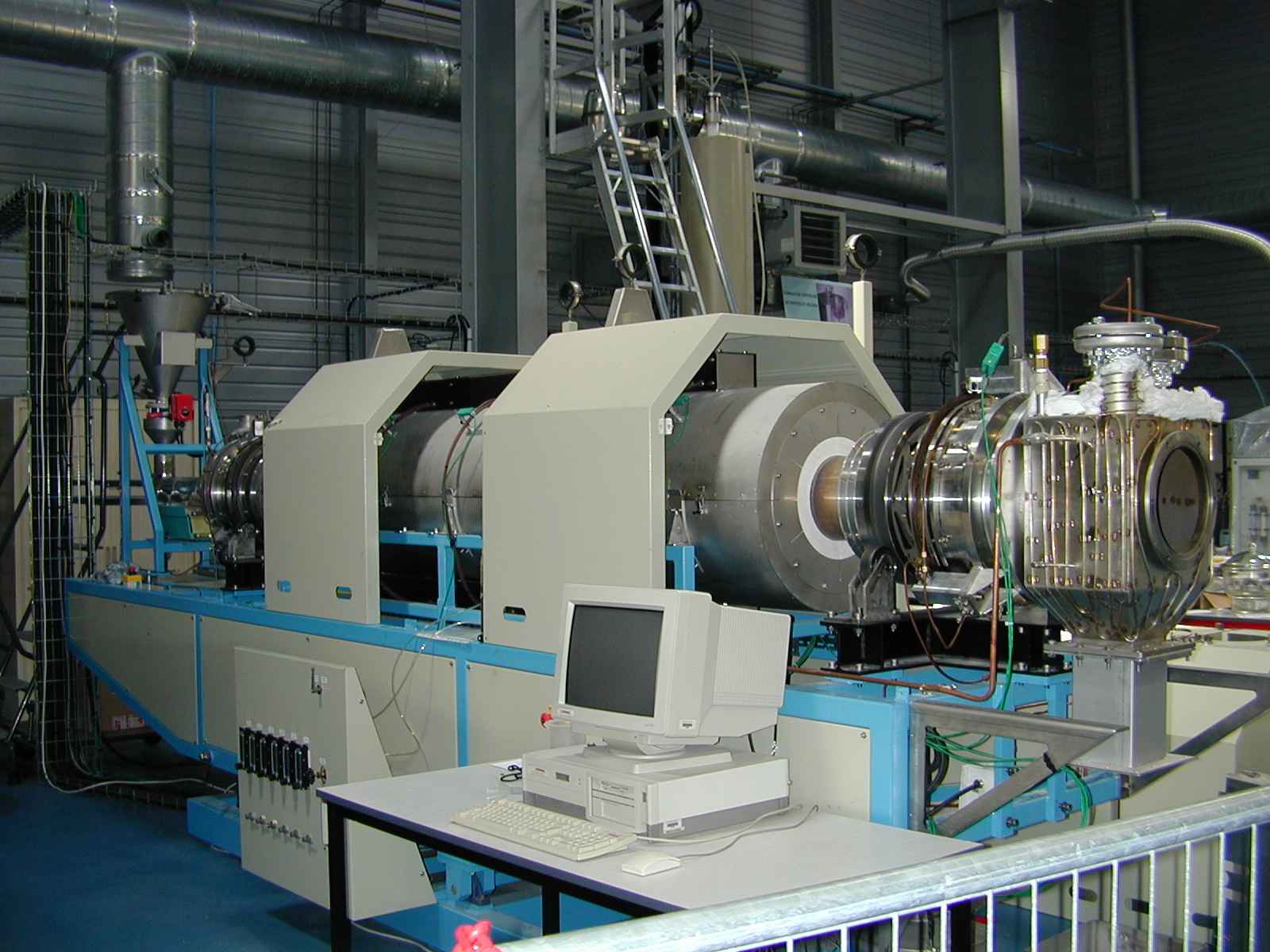

Optimisation of the rotary kiln pyrolysis process - Application to biomass thermal valorisation

Institut National Polytechnique de Toulouse, February 2007

Abstract: Activated carbons are used in many applications such as water treatment, separation of gases, solar refrigeration or gas storage like hydrogen or methane. Rotary kiln is used in industry to produce activated carbon. A study on the optimization of the production of activated carbon in a rotary kiln is presented. Pyrolysis process is examined by using TG experiments in the temperature range [30-800?C]. Kinetic parameters are proposed on the basis of those TG experiments. Laboratory experiments are also conducted in a crossed bed reactor in order to determine kinetics formation of the specific surface area of activated carbons. Those experiments show that a temperature of 450?C and a time duration of pyrolysis of 30 minutes lead to a optimal specific surface of 1477 m2/g. A 1D model of the heated rotary kiln is developed. The model is able to compute mass flow rates of species, temperatures of bed, gas phase and kiln wall, and finally specific surface area of activated carbons. The model of the rotary kiln is finally coupled to a non linear optimization software. An optimal thermal profile of the kiln that maximises the specific surface area of the solid at the exit of the kiln is computed.

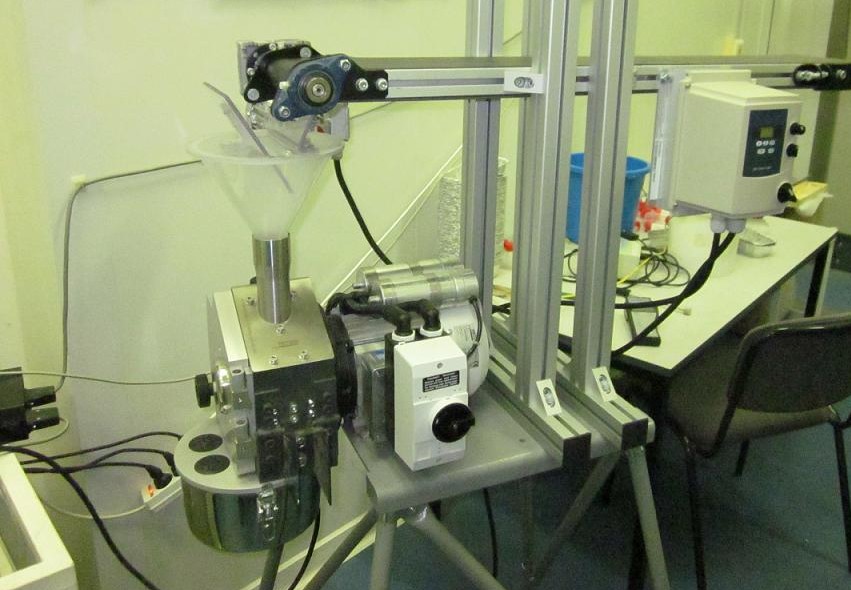

PhD work of Timothée NOCQUET, carried on at CEA Grenoble in collaboration with CIRAD Montpellier

Torréfaction du bois et de ses constituants : Expériences et modélisation des rendements en matières volatiles

Institut National Polytechnique de Toulouse, December 2012

This PhD was awarded with the "Prix Léopold Escande" deserved by Institut National Polytechnique de Toulouse

Abstract: The industrialization of the biomass torrefaction process requires better knowledge of the volatile species release versus operating conditions and feedstock. In this context, the present work aimed at studying solid mass loss and volatile species yields during biomass torrefaction. This transformation was considered on dry wood, at a temperature plateau between 200°C and 300°C and under inert atmosphere. First, torrefaction experiments were conducted under chemical regime on beechwood and its constituents - cellulose, lignin and hemicelluloses - in a thermobalance and in a lab-scale device. The mass balance closure was achieved with values ranging from 97 and 104%. The main volatile species measured were water, formaldehyde, acetic acid and CO2. Smaller amounts of methanol, CO, formic acid and furfural were also quantified. All those gas species were not produced by the three biomass constituents. In particular acetic acid seems to be produced by the degradation of the acetate groups contained in hemicelluloses. The results showed that in a first approximation torrefaction can be described by the additive law up to 250°C. But this law is not valid at 280°C and 300°C because of interactions between cellulose and the two other wood constituents. These interactions lead to a decrease in the torrefaction rate of cellulose. Based on these experimental results, a model of wood torrefaction was developed. It consists in the superposition of "sub-models" describing the torrefaction of each wood constituent. The originality of this model lies in its ability to predict both solid yield and eight volatile species yields depending on cellulose/hemicellulose/lignin wood composition, and to take into account interactions by means of an empirical factor. It was validated on beechwood torrefaction experiments between 220°C and 300°C. Finally, this model highlighted the significant influence of the proportion of hemicellulose and cellulose on torrefaction product yields.

PhD work of Baptiste COLIN, in collaboration with Jean-Louis DIRION, project manager and Patricia Arlabosse

Modélisation de la torréfaction en four tournant et validation expérimentale à l'échelle d'un pilote de laboratoire

To be defended on september 2014

Abstract: The rotary kiln is a classical process to perform heat treatment of a solid load. Wood chips torrefaction can be operated, but the exothermicity of the reaction can lead to uncontrolled overheating of the load and even thermal runaway of the process. The aim of the PhD is to develop a numerical model able to describe the thermal conversion inside a rotary kiln. It will describe the solid flow through the reactor, heat transfer between the load and the reactor, the drying of the load and the subsequent torrefaction reactions. Each of these steps will be validated by specific experiments operated at the pilot scale. It is expected that the model can be used to design large scale rotary kilns and avoid the process control difficulties faced today. The properties of the torrefied wood chips will be characterized into details, with a special focus on the "grindability" of the products depending on the torrefaction severity.

|

|

|

Publications

Pyrolysis of wood impregnated with phosphoric acid for the production of activated carbon: kinetics and porosity development studies

I. Ahmed Hared, J-L. Dirion, S. Salvador, M. Lacroix, S. Rio

Journal of Analytical and Applied Pyrolysis, Volume 79, Issues 1-2, May 2007, Pages 101-105

Impact of Torrefaction on Syngas production from Wood

C. Couhert , S. Salvador , J-M. Commandré

FUEL 88 (2009) 2286-2290

Combustion and gasification characteristics of chars from raw and torrefied biomass

E.M. Fisher, C. Dupont, L.I. Darvell, J.-M. Commandré, A. Saddawi, J.M. Jones, T. Nocquet, and S. Salvador

Bioresource Technology 2012 , vol. 119., p.157-165, DOI information: 10.1016/j.biortech.2012.05.109

Volatile species release during torrefaction of biomass and its macromolecular constituents: Part 1 - experimental study

Timothée NOCQUET, Capucine DUPONT, Jean-Michel COMMANDRE, Maguelone GRATEAU, Sébastien THIERY, Sylvain SALVADOR

Energy, DOI 10.1016/j.energy.2014.02.061

Volatile species release during torrefaction of biomass and its macromolecular constituents: Part 2 - Modelling Study

Timothée NOCQUET, Capucine DUPONT, Jean-Michel COMMANDRE, Maguelone GRATEAU, Sébastien THIERY, Sylvain SALVADOR

Energy 72, p.188-194, 2014.

Wood chips flow in a torrefaction rotary kiln: experiments and modeling

B. Colin, J.L. Dirion, P. Arlabosse, S. Salvador

Chemical Engineering Research and Design 98, pp.179-187, 2015.

Quantification of the torrefaction effects on the grindability and the hygroscopicity of wood chips

Baptiste Colin, Jean-Louis Dirion, Patricia Arlabosse, Sylvain Salvador

FUEL, 197, pp.232-239, 2017.

Experimental study of torrefied wood fixed bed: thermal analysis and source term identification

Amina Bouzarour, Victor Pozzobon, Patrick Perre, Sylvain Salvador

FUEL 234, p.247-255, 2018.

Brieuc Evangelista, Patricia Arlabosse, Alexandre Govin, Sylvain Salvador, Olivier Bonnefoy et al.

Reactor scale study of self-heating and self-ignition of torrefied wood in contact with oxygen

FUEL 214, pp.590-596, 2018.

Congress

Optimization of the pyrolysis of impregnated phosphoric acid wood in a rotary kiln.

I. Ahmed-Hared, J-L. Dirion, S. Salvador, M. Lacroix, S. Rio

17th International Symposium on Analytical & Applied Pyrolysis. May 21 to 26, 2006 - Budapest, Hungary. Poster

Optimisation de la pyrolyse de bois imprégné par de l'acide phosphorique en four tournant

Ahmd Hared I., Dirion J-L., S. Sylvain, Lacroix M.

Récents Progrès en Génie des Procédés - Numéro 96 - 2007, ISBN 2-910239-70-5, Ed. SFGP, Paris, France

Study on gas release during torrefaction of woody biomass and its constituents for injection in entrained flow gasifier

T. Nocquet, C. Dupont, J-M. Commandré, Y. Soudais, C. Boachon, S. Salvador

Symposium on Thermo and Catalytic Sciences for Biofuels and Biobased Products (TCS 2010), September 21-23, Iowa State University

Combustion characteristics of chars from raw and torrefied willow

E.M. Fisher, L.I. Darvell, A. Saddawi, J.M. Jones, C. Dupont, J.-M. Commandré, T. Nocquet, and S. Salvador

7th US National Technical Meeting of the Combustion Institute, hosted by the Georgia Institute of Technology,

Atlanta, GA, March 20-23, 2011.

Study on mass loss and gas release during torrefaction of woody biomass and its constituents for injection in entrained flow gasifier

T. Nocquet, C. Dupont, J.M. Commandre, Y. Soudais, S. Salvador

GPE - 3rd International Congress on Green Process Engineering, 6-8 December 2011 - Kuala-Lumpur (Malaysia)

Modelling of the mass loss and the gas release during torrefaction of woody biomass and its constituents

T. Nocquet, C. Dupont, J-M. Commandre, M. Grateau, M.H. Nguyen, S. Salvador

4th International Conference on Engineering for Waste and Biomass Valorisation, September 10-13, 2012 -

Porto, Portugal - oral presentation

On the validity of the additivity law under torrefaction conditions: experiments on woody biomass and its constituents

T. Nocquet, C. Dupont, J.M. Commandre, M. Grateau, S. Thierry, M.H.Nguyen, S. Salvador

19th International Symposium on Analytical and Applied Pyrolysis, Linz, Austria, 21-25 May 2012. Poster presentation

Mass loss and gas release during torrefaction of woody biomass and its constituents

Nocquet T., Dupont C, Commandré J.M., Grateau M., Thierry S, Nguyen M.H., Salvador S.

20th European Biomass Conference and Exhibition, Milan, Italie, 2012. Oral presentation.

Mass loss and gas release during torrefaction of woody biomass and its constituents

Nocquet T., Dupont C., Commandré J.M., Grateau M., Thierry S, Nguyen M.H., Salvador S.

4th International conference on engineering for waste and biomass valorisation, Porto, Portugal, 2012. Poster presentation.

Torrefaction of Biomass in a Pilot Rotary Kiln: Preliminary study

B. COLIN, J.L. DIRION, P. ARLABOSSE, S. SALVADOR

4th International Conference on Engineering for Waste and Biomass Valorisation, Porto, September 2012, Poster presentation.

Torréfaction en four tournant : Etude de l'écoulement des plaquettes de bois

Baptiste Colin, Jean-Louis Dirion, Patricia Arlabosse, Sylvain Salvador

SFGP2013 - XIVe congrès de la Société Française de Génie des Procédés

Kinetic model of condensable co-products release during biomass torrefaction

T. Nocquet, C. Dupont, J.M. Commandre, M. Grateau, S. Thiery, M.H.Nguyen, S. Salvador

ISGC2, 21-24 Mail 2013, La Rochelle, France

Torréfaction en four tournant : étude de l'écoulement de plaquettes de bois

COLIN B., DIRION J-L., ARLABOSSE P., SALVADOR S.

Récents Progrès en Génie des Procédés, Numéro 104 - 2013, ISSN: 1775-335X ; ISBN: 978-2-910239-78-7, Ed. SFGP, Paris, France

Experimental Study of Wood Chips Torrefaction in a Pilot-Scale Rotary Kiln

B. Colin, J.L. Dirion, P. Arlabosse, S. Salvador

iconBM: international conference on BioMass, Florence, May 2014 (oral communication)

Chemical Engineering Transactions, Vol. 37, 2014.

KINETIC MODEL OF CONDENSABLE CO-PRODUCTS RELEASE DURING BIOMASS TORREFACTION

Timothée NOCQUET, Capucine DUPONT, Jean-Michel COMMANDRE, Maguelone GRATEAU, Sébastien THIERY, Sylvain SALVADOR

iconBM: International Conference on Biomass, 4-7 May 2014, Florence ITALY

Chemical Engineering Transactions, Vol. 37, 2014.

Wood chips torrefaction in a pilot-scale rotary kiln

Baptiste Colin, Jean-Louis Dirion, Patricia Arlabosse, Sylvain Salvador

8th iCIPEC conference, Hangzhou, China, Oct. 15-18 2014

TORREFACTION OF WOOD CHIPS IN A PILOT-SCALE ROTARY KILN: EXPERIMENTAL RESULTS AND MODELLING

B. COLIN, J.-L. DIRION, P. ARLABOSSE and S. SALVADOR

5th International Conference on Engineering for Waste and Biomass Valorisation - Aug. 24-28, 2014 - Rio de Janeiro, Brazil

Modelling of torrefaction kinetics of beech wood

Jean-Louis Dirion, Baptiste Colin, Patricia Arlabosse, Sylvain Salvador

10th European Congress of Chemical Engineering ECCE10, September 27-October 1st 2015, Nice, France, Oral presentation of P. Arlabosse.

Études expérimentales et modélisation du phénomène d'auto-échauffement, application au refroidissement de plaquettes de bois torréfiées

Brieuc Evangelista, Patricia Arlabosse, Alexandre Govin, Sylvain Salvador, Olivier Bonnefoy et al.

Journée Scientifique du CODEGEPRA 2016, CODEGEPRA Comité de DÉveloppement du GÉnie des Procédés en Rhône-Alpes Auvergne, Nov 2016, Saint-Martin d'Hères, France

Experimental study of self-heating phenomena during torrefaction of spherical wood particles

Brieuc Evangelista, Patricia Arlabosse, Elsa Weiss-Hortala, Alexandre Govin, Sylvain Salvador et al.

6th International Conférence on Engineering for Waste and Biomass valorisation - WasteEng2016, WasteEng conference series; Mines Albi-Carnaux, May 2016, Albi, France

Experimental study of self-heating phenomenon at the reactor-scale. Safety assessment of a fixed-bed filled with torrefied wood chips

Brieuc Evangelista, Olivier Bonnefoy, Alexandre Govin, Patricia Arlabosse, Sylvain Salvador et al.

10th World Congress of Chemical Engineering- WCCE10, Anque; Enginyers Industrials de catalunya;

SEQUI; A IQS, Oct 2017, Barcelone, France. pp.2448

ETUDE EXPERIMENTALE ET NUMERIQUE DE LA REACTION ENTRE LE BOIS TORREFIE ET L'OXYGENE A FAIBLE TEMPERATURE

Evangelista Brieuc, Salvador Sylvain, Govin Alexandre Arlabosse, Bonnefoy Olivier, Dirion Jean-Louis

16ème Congrès de la Société Française de Génie des Procédés, 11 au 13 Juillet 2017, Nancy, France.